N95 Respiratory Protection Alternatives

WHAT TO USE WHEN AN N95 IS NOT AVAILABLE

Between heightened demand worldwide and the Defense Production Act to supply American healthcare workers with N95 masks, it’s virtually impossible for contractors outside the healthcare sector to get these masks. But did you know that you can use a half- or full-face respirator with P100 filters in place of an N95 mask?

Jon-Don has both half-face and full-face respirators available, as well as the P100 filters you need to use with them. Your health and safety is our top priority as we help you tackle your toughest jobs.

HALF-FACE RESPIRATORS

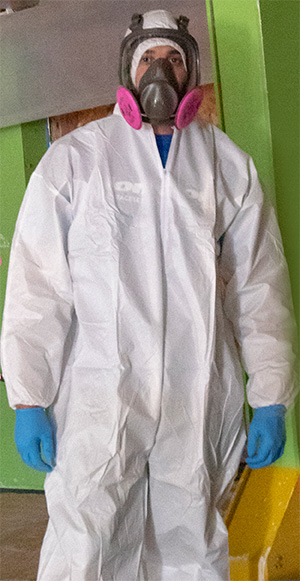

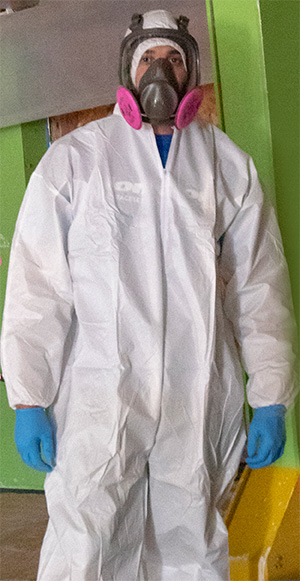

FULL-FACE RESPIRATORS

P100 CARTRIDGES

*Honeywell North and 3M Cartridges are proprietary and will not fit any other brand/style of mask. You must use the same brand mask and cartridge.

When selecting the appropriate respirator for you and your team, you must consider the hazard and the effects it can have on you. For example, could the hazard irritate the eyes? Do you need splash and spray protection? These answers would determine if you need a half-face or full-face respirator.

The first part of the filter’s classification uses the letters N, R, or P to indicate its ability to function when exposed to oils.

N-Series Filters

These filters are restricted to use in those atmospheres free of oil aerosols. They may be used for any solid or liquid airborne particulate hazard that does not contain oil. Generally, these filters should be used and reused subject only to considerations of hygiene, damage, and increased breathing resistance.

R-Series Filters

Filters intended for removal of any particle including oil-based liquid aerosol. They may be used for any solid or liquid airborne particulate hazard. If the atmosphere contains oil, the R-series filter should be used only for a single shift (or up to 8 hours continuous or intermittent use).

P-Series Filters

Intended for removal of any particle including oil-based liquid aerosols. They may be used for any solid or liquid particulate airborne hazard. NIOSH recommends that respirator manufacturers establish time use limitations for all P-series filters.

P-Series filters should be used and reused for no more than 40 hours of use or 30 days, whichever occurs first, in atmospheres that contain oil aerosols unless the filter needs to be changed for hygiene reasons, is damaged, or becomes difficult to breathe through before the time limit is reached.

When used in atmospheres containing non-oil aerosol, P-series filters should be used and reused subject to conditions of hygiene, damaged, and increased breathing resistance.

The numbers 95 and 100 indicate the percentages of particles the filters remove.

The 95 means the filter removes at least 95% and the 100 means the filter removes at least 99.97%. Therefore, an N95 filter is not resistant to oil and removes at least 95% of the most penetrating particles. And the P100 filter is oil-proof and removes at least 99.97% of the most penetrating particles.

| PROTECTION AGAINST CRYSTALLINE SILICA |

Crystalline silica is found in sand, stone, concrete, brick, and mortar. When workers cut, grind, drill, or crush materials that contain crystalline silica, very small dust particles are created. Workers who are exposed to silica dust are at increased risk of developing serious illnesses and diseases. OSHA has implemented respiratory standards that must be followed when grinding or polishing concrete as well as when sawing drywall or wood studs in a wall.

For additional information on OSHA’s Crystalline Silica Standard, visit our info center.

| CLEANING AND STORAGE PROCEDURES FOR REUSABLE RESPIRATORS |

INSPECTION

Respirators must be inspected before each use to ensure good operating condition.

The facepiece must be repaired or replaced if there are damaged or defective parts. The following inspection procedure is suggested:

-

Check facepiece for cracks, tears, and dirt. Be certain facepiece, especially face seal area, is not distorted.

-

Examine inhalation valves for signs of distortion, cracking, or tearing.

-

Make sure the head straps are intact and have good elasticity.

-

Examine all plastic parts for signs of cracking or fatiguing. Make sure filter gaskets or seal areas are in good condition.

-

Remove exhalation valve cover and examine exhalation valve and valve seat for signs of dirt, distortion, cracking, or tearing. Replace exhalation valve cover.

-

Inspect lens of full facepiece for any damage that may impair respirator performance or vision.

CLEANING AND STORAGE IS RECOMMENDED AFTER EACH USE

Alcohol wipes may be used as an interim method in the cleaning schedule for individually assigned respirators, but they must not be the only method in place. During fit testing, wipes may also be used between employees being tested. However, these respirators must be thoroughly cleaned at the end of each day, using procedures in OSHA appendix B-2 of 29 CFR 1910.134.