Steps to Ensure Compliance With the New OSHA PEL Standards

The information provided in the following sections is intended to be a helpful guide and summary of the OSHA requirements; however, it is not a substitute for the official information provided within the standard. Please refer to the OSHA Small Entity Compliance Guide for complete details.

Exposure Determination

OSHA has given employers two ways to determine crystalline silica exposure levels.

Option 1: Alternative Exposure Control Methods

This method requires that you control silica with your own methods and then measure your employees’ silica exposure through medical testing and other procedures, such as air monitoring.

The specific procedures for analyzing air samples are detailed in Appendix A of the procedure.

This can be expensive and complicated. Plus, if you discover that the exposure is at or above OSHA’s requirement, you must find better methods of limiting silica dust exposure.

Option 2: Determine Exposure Through Table 1 (preferred)

OSHA has already done some of the legwork for you and identified procedures you need to put into place to ensure any silica dust levels remain within the permissible exposure limit (PEL).

The activities and dust control methods can be found on Table 1 of the standard.

These measures are typically very easy and inexpensive to implement. Plus, employers who follow Table 1 of the standard correctly are not required to measure their worker’s exposure to silica and are not subject to the PEL.

See specific dust control methods for three common operations performed by concrete operators as outlined by Table 1:

Create a Written Exposure Plan

All employers covered by the standard—even if you fully implement all the specified exposure controls on Table 1—must develop and implement a written exposure control plan.

Your plan must include a description of the following:

- The workplace tasks involving exposures to respirable crystalline silica

- The engineering controls, work practices, and respiratory protection used to limit employee exposure to respirable crystalline silica for each task

- The housekeeping methods used to limit employee exposure to respirable crystalline silica

- The procedures used to restrict access to work areas, when necessary, to limit the number of employees exposed to respirable crystalline silica

OSHA’s respirable crystalline silica standard requires employers to review and evaluate the effectiveness of the written exposure plan at least once a year and to update it as necessary.

To make it easy for employers to develop a plan tailored to their business, we highly recommend using the Create-a-Plan Tool at https://plan.silica-safe.org/. The easy-to-use tool will walk you through all essential areas of your written exposure plan to ensure compliance.

The Written Exposure Control Plan must contain descriptions of the tasks that create silica exposure, the controls, practices, and any respiratory protection used to limit exposures.

Competent Person Inspections

OSHA expects routine observations of dust-generating tasks to be made by a designated “competent person” at your company. The person is expected to take prompt and quick action with any increase of visible dust.

According to OSHA, a competent person is someone who:

- Can identify existing and foreseeable respirable crystalline silica hazards

- Is authorized to promptly eliminate or minimize silica hazards

- Has the knowledge and ability to implement the written exposure control plan.

The employer can designate any of his/her employees (including the employee who does the work on a job site) to be a competent person if the individual is qualified.

What about a one-man crew?

Employees who go to job sites alone can be a designated competent person if they know how to properly implement controls on the tools they use, can recognize if the controls are not working, and can correct the non-working control.

Housekeeping

All employers covered by the OSHA respirable crystalline silica standard (whether you’re implementing Table 1 control methods or your own) must follow proper housekeep-ing procedures to limit employees’ exposure to respirable crystalline silica.

Housekeeping Do’s and Don’ts

- DON’T allow dry brushing or dry sweeping

- DO allow wet sweeping

- DO allow HEPA-filtered vacuuming

- DON’T allow cleaning of surfaces or clothing with compressed air (unless the compressed air is used together with a ventilation system that effectively captures the dust cloud)

Are there exceptions to the rules?

Situations in which no acceptable cleaning method (such as wet sweeping and HEPA-filtered vacuuming) can be used are expected to be very rare. In those rare cases where the employer needs to use cleaning methods, such as dry sweeping, dry brushing, or compressed air, the employer must be able to show why cleaning methods that decrease employee exposures are not feasible.

Do I have to follow the housekeeping requirements at all times?

The housekeeping requirements in the silica standard apply only where cleaning “could contribute to employee exposure to respirable crystalline silica.” This includes cleanup from tasks, such as concrete drilling, cutting, grinding, or crushing.

Employers are not required to follow these housekeeping requirements when cleaning ordinary soil, large debris, and non-silica-containing materials, such as sawdust.

Medical Surveillance

The OSHA standard requires employers to provide medical screening and surveillance to allow for early identification of crystalline-silica-exposure-related health effects.

Silica-related diseases can be fatal. A variety of organs can be affected and it can even put individuals at risk for contracting latent tuberculosis, which makes it a public health threat as well.

Which employees must be offered medical surveillance?

According to paragraph (H) of the standard, employers must make an initial or periodic medical examination available to employees who will be required by silica standard to wear a respirator for 30 or more days in the coming year (the next 365 days). Even if the employee only has to wear a respirator for a few minutes during one day, it counts as a full day of respirator use.

How frequent should the exams be?

Employers must offer medical examinations:

- Within 30 days of initial assignment, unless the employee has already had an examination the meets the silica standard requirements within the last 3 years

- Every 3 years from the employee’s last examination that met the requirements of the silica standard, or more frequently, if recommended by the PLHCP

Who should conduct the exams?

Medical exams must be conducted by a physician or other licensed healthcare professional (PLHCP). The PLHCP should have a thorough knowledge of silica-related health effects.

What should the medical exam cover?

The following is a list of the required components of medical surveillance under the respirable crystalline silica standard.

- History (medical/health history and work history)

- Physical examination

- TB testing

- Pulmonary function testing

- Chest X-ray

What if my employee is referred to a specialist?

The employer must make the specialist examination available within 30 days of receiving the written medical opinion that includes the PLHCP’s recommendation for a specialist examination. The specialist must be either an American Board Certified Specialist in Pulmonary Disease or an American Board Certified Specialist in Occupational Medicine.

The employer must ensure the specialist:

- Receives the same information that the employer is required to provide the PLHCP (see above)

- Explains the results of the medical examination to the employee and provides each employee with a written medical report within 30 days of the examination

- Provides the employer a written medical opinion within 30 days of the examination.

Employer responsibilities...

- Employers must give the following required information to the physician or other licensed health care professional (PLHCP) who will be conducing the examination.

- A description of the employee’s former, current, and anticipated duties as they relate to the employee’s occupational exposure to respirable crystalline silica

- The employee’s former, current, and anticipated levels of occupational exposure to respirable crystalline silica

- A description of any personal protective equipment used or to be used by the employee, including when and for how long the employee has used or will use that equipment

- Information from records of employment-related medical examinations previously provided to the employee and currently within the control of the employer

- Medical surveillance must be provided at no cost to the employee

- Medical surveillance must take place at a reasonable time and place

- If getting to the medical exam requires the employee to travel away from the worksite, the employer is required to cover the cost of travel

- The employer must also pay employees for time spent traveling and taking medical examinations

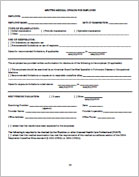

Sample Medical Form Templates

Click to download the following sample medical forms required by the OSHA Crystalline Silica Standard. Employers can present these forms to the PLHCP and, if necessary, any specialist practitioners as recommended by the PLHCP.

Written Medical Report for Employee

Once the medical surveillance exam is completed, the employer must ensure that the PLHCP explains to the employee the results of the medical exam and provides the employee with a written medical report within 30 days of the examination. The employer does not receive a copy of this report.

Written Medical Opinion for Employer

Once the medical surveillance exam is completed, the employer must ensure that the PLHCP provides the employer and the employee with a written medical opinion within 30 days of the employee examination.

Authorization for Crystalline Silica Opinion to Employer

This form should be signed by the employee to clarify what information the PLHCP may release to the employer in the written medical opinion. A copy should be kept by the employee, the employer, and the PLHCP.

Communication of Hazards

Employers must train and inform employees covered by the silica standard about respirable crystalline silica hazards and the methods the employer uses to limit their exposures to those hazards. Employers must cover the cost of training and must pay employees for the time spent in training.

What should training topics cover?

The employer must ensure that employees trained under the silica standard can demonstrate knowledge and understanding of the following:

- Health hazards associated with respirable crystalline silica exposure

- Specific workplace tasks where employees might be exposed

- Specific measures the employer is implementing to protect employees, including engineering controls, work practices, and respirators to be used. This training must be specific for the task that each employee performs. So employees who handle tools and equipment will receive different information from laborers who do not operate tools.

- Identity of the competent person(s) designated by the employer

- Contents of the respirable crystalline silica standard

- Purpose and description of the medical surveillance program

Topics that employers could communicate include:

- The employer responsibilities for medical surveillance listed in the previous section

- The symptoms associated with respirable crystalline silica-related diseases

- The importance of keeping copies of all medical reports and opinions to avoid unnecessary testing

- That employers cannot retaliate or discriminate against employees for participating in medical surveillance

Make a Copy of the Standard Available

Employers must make a copy of the respirable crystalline silica standard available at no cost to each employee covered by the standard. This could simply involve allowing employees to view a printed or electronic copy in a reasonable location.

What training methods should I use?

The silica standard does not require the employer to use any particular method for training employees. Training must be done in a manner and language that employees understand. Employers can determine if employees know and understand the training topics through discussion of the required training subjects, written tests, or oral quizzes.

When should employees be trained?

Employees must be trained at the time they are assigned to a position involving exposure to respirable crystalline silica.

So if you are planning on training your whole crew on Friday, but an untrained employee is starting a new job on Tuesday, you cannot wait until Friday to provide the training he needs.

Additional training must be provided as often as necessary to ensure that employees know and understand respirable crystalline silica hazards and the protections available in their workplace.

Examples of when additional training would be required include:

- When the employer asks an employee to perform a task that is new to that employee;

- When the employer introduces new protections (for example, an employer who was having employees use a handheld grinder with wet method controls decides to have employees use a handheld grinder with a dust collection system); or

- When an employee is working in a manner that suggests he/she has forgotten what was learned in training.

Recordkeeping

Employers are required to make and keep accurate records to demonstrate compliance with the standard as well as assist in diagnosing and identifying workplace-related illnesses.

Employers are required to keep the following types of records:

- Air moitoring data*

- Objective data*

- Medical Surveillance

*Employers who follow Table 1 of the standard are not required to take air samples or objective data to measure silica exposures.

If you do not follow Table 1, you must follow the procedures listed in Appendix A of the standard.

What records do I need to keep for medical surveillance?

The employer must make and keep an accurate record for each employee provided medical surveillance under the standard. The record must include the following information about the employee:

- Name and social security number;

- A copy of the PLHCPs’ and specialists’ written opinions; and

- A copy of the information that the employer is required to provide to the PLHCPs and specialists (see Medical Surveillance section above)

Records must be thorough and accessible

Exposure and medical records must be kept and made available to employees, their representatives, and OSHA in accordance with OSHA’s access to employee exposure and medical records regulation.

Don’t throw anything out!

A separate OSHA regulation (29 CFR 1910.1020, Access to Employee Exposure and Medical Records) addresses requirements for maintaining exposure and medical records.

In general, exposure records (including air monitoring and objective data) must be kept for at least 30 years, and medical records must be kept for at least the duration of employment plus 30 years.

It is necessary to keep these records for extended periods because silica-related diseases such as cancer often cannot be detected until several decades after exposure.

However, if an employee works for an employer for less than one year, the employer does not have to keep the medical records after employment ends, as long as the employer gives those records to the employee.