Written By: Bad Axe Restoration Products

It has long been said that "necessity is the mother of invention." That saying cannot be any truer than in the restoration industry.

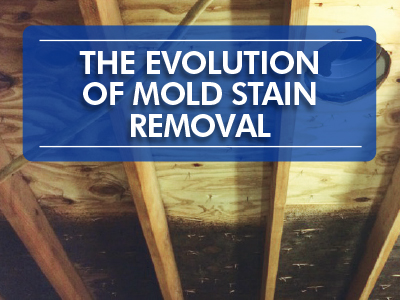

For years, disaster recovery and mold remediation professionals struggled with the challenge of removing mold stains from structural building materials. There were two primary options:

- The delamination of a surface through sanding, wire brushing, or abrading; or

- The chemical reduction of staining using hydrogen peroxide formulations.

Delamination activities, like soda blasting and ice blasting, proved to be costly, labor-intensive, and time-consuming. While the application of peroxide products provided mediocre results at best. Peroxides were either too weak or obscenely strong and difficult for end-users to apply.

Clearly, the industry needed a third option—sodium hypochlorite.

In this article, we’ll explore the history and advantages of sodium hypochlorite, and how restoration professionals can use these products to manage customer expectations.

What Is Sodium Hypochlorite?

Sodium hypochlorite is the active ingredient in bleach. Its chemical formula is NaOCl, meaning it is composed of sodium, oxygen, and chlorine. When sodium chlorite comes into contact with organic matter, heat, or sunlight, it breaks down into salt (NaCl) and water (H2O).

How Was Sodium Hypochlorite Used Within the Restoration Industry?

For years, bleach was frowned upon by the restoration industry for mold stain removal, primarily because anyone could go buy bleach and spray it on a surface. To a degree, its ease of use wrongfully minimized the importance and legitimacy of its use during professional mold remediation.

In the early 2000s, contractors like the Mold Solutions Group began using sodium hypochlorite solutions with remarkable success. Pioneered by the manufacturer currently known as Bad Axe Restoration Products, sodium hypochlorite solutions like MMR Mold Stain Remover have become commonplace for industry mold-stain removal projects.

The design of mold stain removers relied on the KISS concept: “Keep It Simple, Stupid.” Ultimately the most effective solution for bleaching out mold stains was using bleach-based products (sodium hypochlorite).

Can Sodium Hypochlorite Be Used on Porous Surfaces?

While bleach alone is ideal for hard, non-porous surfaces, like tile, countertops, tubs, and shower basins, it has proven less effective on semi-porous building materials, such as wood, concrete, cinder block, Hardiboard, and drywall.

Through trial-and-error efforts and working closely with restoration contractors, Bad Axe developed modified bleach formulations that could be applied to porous surfaces to treat visible mold staining. To be effective on more porous building materials, the bleach required more surface tension.

As a result, surfactants were incorporated into formulations to allow the bleach to soak deeper into the wood. This yielded exceptional bleaching characteristics along with a decomposition of the mold’s root system.

How Is Sodium Hypochlorite Used During Mold Remediation Jobs?

Mold remediation efforts require containment and sometimes removal of materials. Source removal is still a vital aspect of creating a safe environment. Activities such as wiping, HEPA vacuuming, air scrubbing, air washing, and disinfecting are also key components in most jobs.

From a consumer perspective, those source removal activities rarely provide a visual confirmation that the mold has been addressed (short of verification testing).

This is why the chemical application to remove the mold stain provides a customer with an additional level of perspective that the mold has been professionally dealt with. Additionally, a clean surface can be used as a basis for comparison to ensure that mold has not re-grown on a surface.

Mold Abatement Jobs Made Easier

Mold remediation and abatement can be a complicated process. Chemical advances like MMR Mold Stain Remover are an important tool to achieve more positive outcomes and satisfy customers on every job.

The Bad Axe tagline, “Clean It, Kill It, Contain It and Clear It” was created to place chemicals and products into certain “outcome-based” categories. Understanding what chemical product creates a certain result and outcome is essential. Keeping it simple, safe, and effective is a goal of manufacturers like Bad Axe and their distribution partners like Jon-Don.

For more information about mold stain removers or for help troubleshooting your next mold abatement job, contact a Jon-Don Restoration Expert at 800-556-6366.

About Bad Axe Restoration Products

Bad Axe Products, LLC, is a manufacturer of restoration industry products, including MMR mold stain remover. MMR mold stain remover is the industry’s premier mold stain remover. It is a commercial-grade mold and mildew stain remover formulated to immediately eliminate mold and mildew stains present on wood and other hard surfaces. MMR mold stain remover penetrates soiled areas almost instantly, leaving surfaces clean and free from mold stains.

Comments